Not known Facts About Stahl Specialty Company

Table of ContentsThe Stahl Specialty Company IdeasStahl Specialty Company - The FactsRumored Buzz on Stahl Specialty CompanyThe 45-Second Trick For Stahl Specialty CompanyStahl Specialty Company Things To Know Before You Get This

The subtle difference depends on the chemical web content. Chemical Contrast of Cast Light weight aluminum Alloys Silicon advertises castability by lowering the alloy's melting temperature level and enhancing fluidness throughout casting. It plays a vital function in permitting detailed molds to be loaded properly. In addition, silicon contributes to the alloy's toughness and put on resistance, making it important in applications where sturdiness is essential, such as vehicle components and engine components.It additionally boosts the machinability of the alloy, making it much easier to process right into ended up products. In this method, iron adds to the total workability of light weight aluminum alloys.

Manganese adds to the strength of light weight aluminum alloys and enhances workability. Magnesium is a light-weight component that supplies stamina and impact resistance to aluminum alloys.

Zinc improves the castability of aluminum alloys and helps control the solidification procedure throughout casting. It improves the alloy's stamina and solidity.

The smart Trick of Stahl Specialty Company That Nobody is Talking About

Since aluminum-silicon alloys have good spreading homes, high gas homes, basic processes, and superb corrosion resistance, aluminum-silicon alloys are most commonly used in the die-casting sector in your home and abroad. At the very same time, aluminum-silicon alloys are also relatively very early and commonly recognized alloys created and made use of in die-casting. After continual research study and improvement, a lot of the existing international mainstream aluminum-silicon alloys have been completed and are nothing more than A356, A360, A380, ADC12, B390, and A413.

The key thermal conductivity, tensile strength, return stamina, and elongation vary. Amongst the above alloys, A356 has the greatest thermal conductivity, and A380 and ADC12 have the most affordable.

Facts About Stahl Specialty Company Uncovered

In accuracy casting, 6063 is fit for applications where detailed geometries and top quality surface finishes are vital. Instances include telecommunication enclosures, where the alloy's superior formability permits sleek and visually pleasing designs while maintaining architectural integrity. In the Lights Solutions industry, precision-cast 6063 elements produce sophisticated and reliable lighting fixtures that require intricate shapes and excellent thermal performance.

(https://linktr.ee/stahlspecialc)

The A360 shows premium elongation, making it excellent for complicated and thin-walled parts. In accuracy spreading applications, A360 is fit for sectors such as Customer Electronic Devices, Telecommunication, and Power Tools.

In accuracy spreading, aluminum 413 shines in the Consumer Electronic Devices and Power Devices markets. It's frequently made use of to craft complex parts like smart device housings, cam bodies, and power tool housings. Its accuracy is exceptional, with limited tolerances as much as 0.01 mm, ensuring remarkable item assembly. This alloy's exceptional deterioration resistance makes it an exceptional selection for outdoor applications, making sure lasting, resilient items in the mentioned industries.

5 Simple Techniques For Stahl Specialty Company

As soon as you have actually determined that the aluminum pass away casting procedure is appropriate for your task, an essential next step is picking one of the most appropriate alloy. The light weight aluminum alloy you choose will considerably affect both the spreading process and the buildings of the end product. Due to this, you need to make your choice thoroughly and take an enlightened strategy.

Establishing one of the most appropriate light weight aluminum alloy for your application will indicate weighing a broad range of characteristics. These relative alloy qualities adhere to the North American Pass Away Casting Organization's standards, and we have actually split them into two classifications. Aluminum Castings. The very first classification addresses alloy qualities that affect the production process. The 2nd covers characteristics influencing the residential properties of the final item.

The alloy you pick for die our website spreading directly impacts several facets of the spreading procedure, like exactly how simple the alloy is to collaborate with and if it is prone to casting defects. Hot cracking, also referred to as solidification breaking, is a regular die spreading defect for aluminum alloys that can cause inner or surface-level splits or fractures.

9 Simple Techniques For Stahl Specialty Company

Certain aluminum alloys are extra at risk to warm cracking than others, and your selection needs to consider this. An additional typical flaw found in the die spreading of aluminum is pass away soldering, which is when the actors sticks to the die wall surfaces and makes ejection challenging. It can damage both the actors and the die, so you should seek alloys with high anti-soldering residential or commercial properties.

Deterioration resistance, which is currently a remarkable feature of light weight aluminum, can differ considerably from alloy to alloy and is a vital particular to think about depending upon the environmental problems your product will certainly be subjected to. Use resistance is another property frequently looked for in light weight aluminum items and can differentiate some alloys.

Hallie Eisenberg Then & Now!

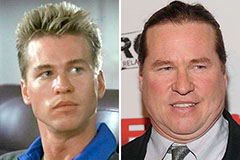

Hallie Eisenberg Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!